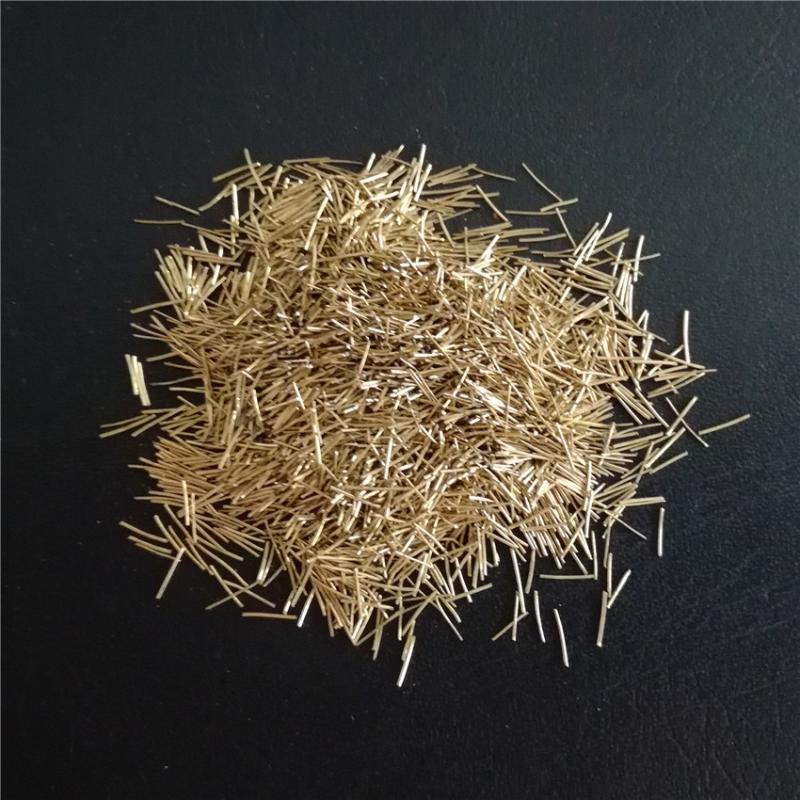

It‘s the special kind of metal fiber with very high of compressive intensity, tensile intensity, crack resistance.It is widely uesd in high-speed rail precast,RPC cover Board,important projects components and exterior painting. It can improve the performances of the conceret,such as anti-tensile, anti-compressive,shear intensity,impermeability,impact resistance,fatigue resistance,and so on. Tensile Strength > 2800MPA0.2 ~0.3mm diameterLength as your requestApplication Its widely used in highway, bridge, tunnel, airport runway, industrial floor, hydraulic project and bas

Contacta ahora

Carbon Steel Milling Fiber For Concrete and Cement In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely Carton Steel Fiber reinforced concrete Fibers.

Contacta ahora

Product Details With 100% polypropylene as raw material,Polypropylene PP fiber mesh is produced by special technology. It appears net-like structure with many mono-filament connected.

Contacta ahora

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contacta ahora

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contacta ahora

Product Details Polypropylene mono-filament fiber can significantly improve the bond performance between fiber and cement mortar, concrete.

Contacta ahora

Macro Structural Polypropylene FibersMacro Polypropylene fibers ,also known as plastic steel fiber,is refined from polypropylene as the main raw material through a special production process.The surface of polypropylene crude fiber is rough and uneven.It is a new type of reinforced and toughening material.The product not only has the function of steel fiber,but also has the advantages of synthetic fiber.It can replace steel fiber for the crack resistance enhancement of cement concrete.

Contacta ahora

High Tensile Strength Macro Steel Fibers for Concrete Reinforcement In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely steel fiber reinforced concrete.

Contacta ahora

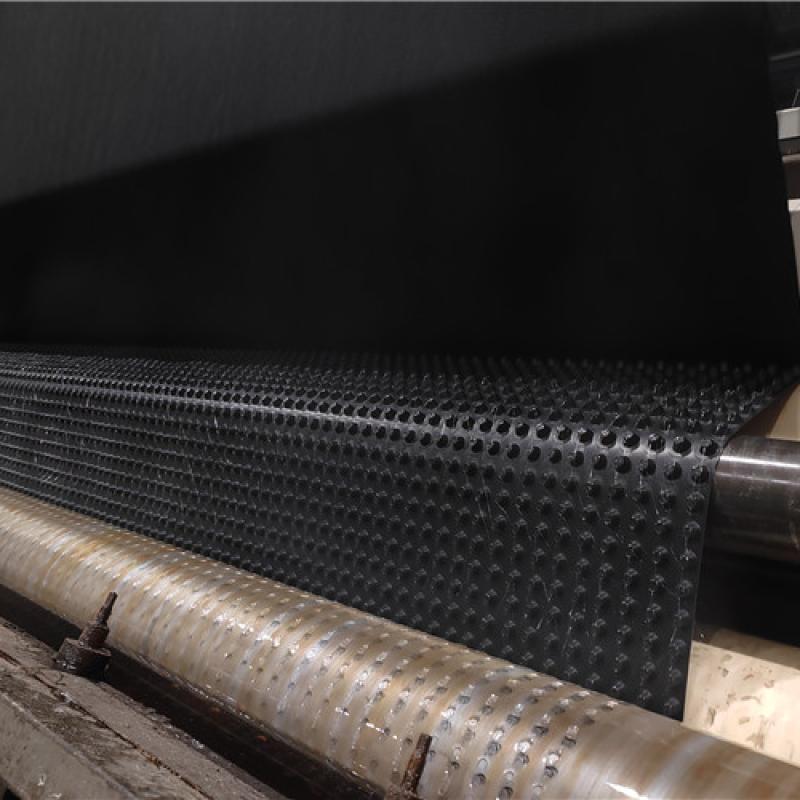

Product DetailsStorage and drainage board is made of PP material,an new geotechnical material which storage a set of water drainage,water storage function,and also have the water drainage,water storage,breathable,moisture,thermal insulation,prevent multiple functions such as plant roots destruction for concrete structures.Used combination with geotextile can avoid the fine particle plugging water storage tank and drainage channel,keep clear of drainage and air circulation,which is widely used in garden greening projects.ParameterModel MaterialDrain height(mm)Compressive strength(Mpa)Specificat

Contacta ahora

Product DetailsGarage and drainage board is product of pp material,an new geotechnical fabric which garage a set of water drainage,water garage characteristic,and also have the water drainage,water storage,breathable,moisture,thermal insulation,save you multiple features inclusive of plant roots destruction for concrete systems.Used combination with geotextile can avoid the first-rate particle plugging water storage tank and drainage channel,hold clear of drainage and air circulation,that's extensively utilized in garden greening initiatives.ParameterModel MaterialDrain height(mm)Compressi

Contacta ahora