Product DetailsSteel plastic geogrid is characterized via using high corrosion resistance and fantastic placed on resistance.

Contacta ahora

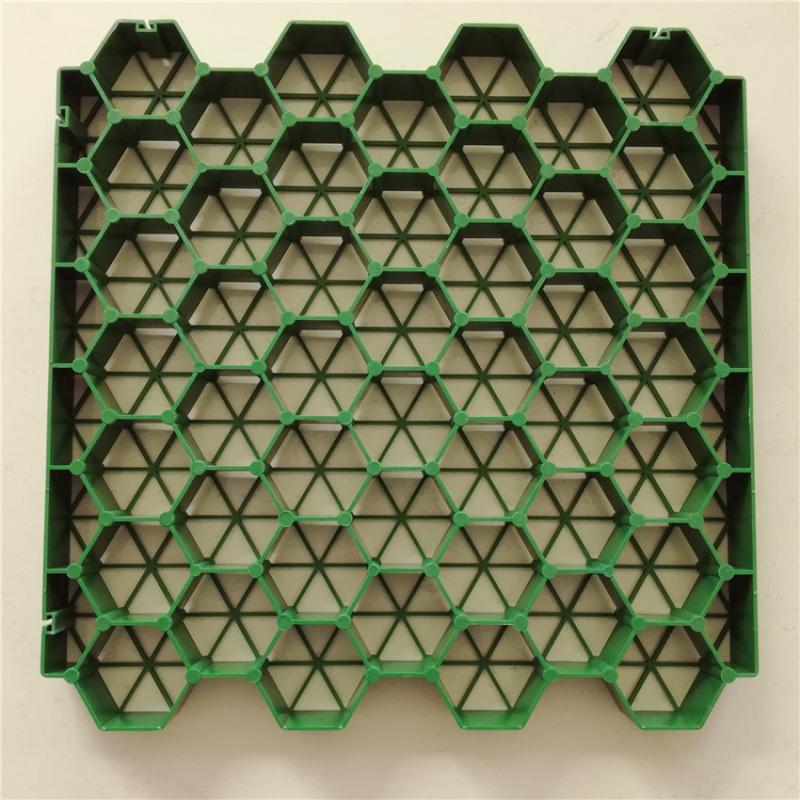

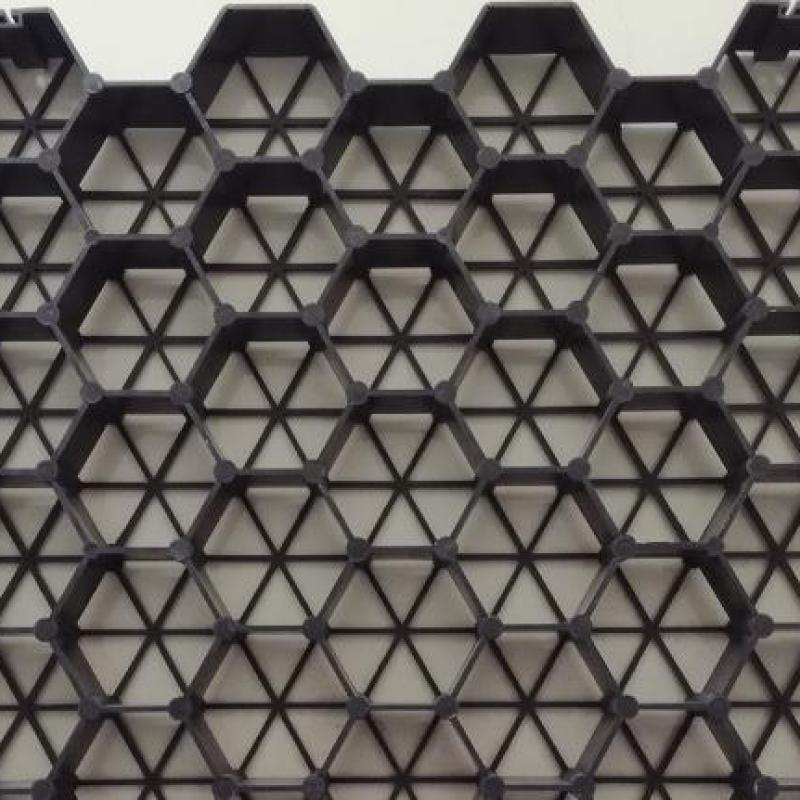

Plastic Grass Paving Grid 50mm for Lawn Parking Lot DrivewayPlastic grass paving grid is made from PP or HDPE (high-molecular polyethylene) with fiber and age resistor, using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It’s widely used in parking lot, fire exit, fire climbing surface, pavement etc.

Contacta ahora

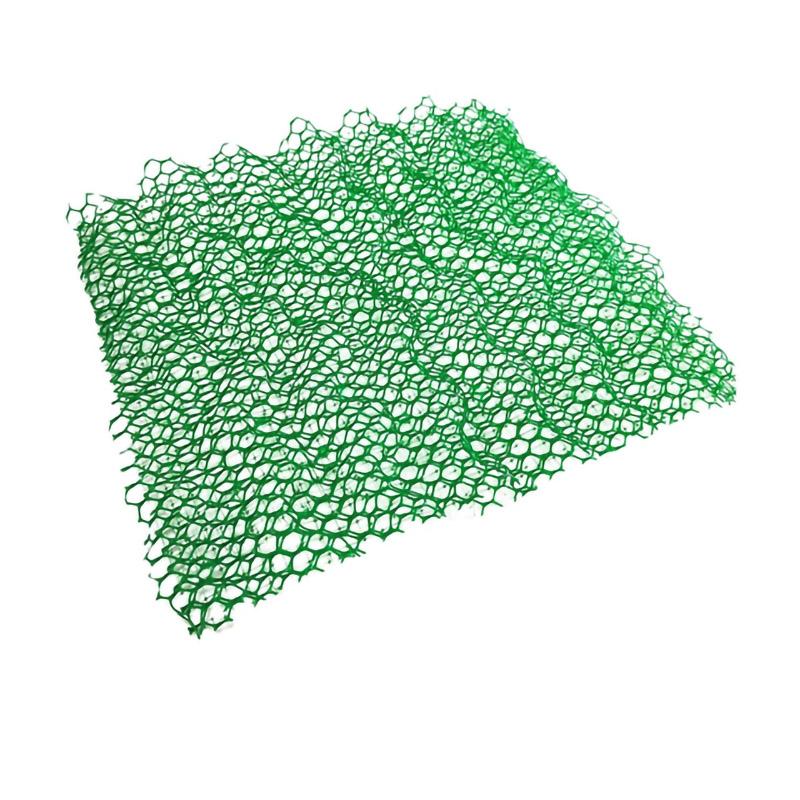

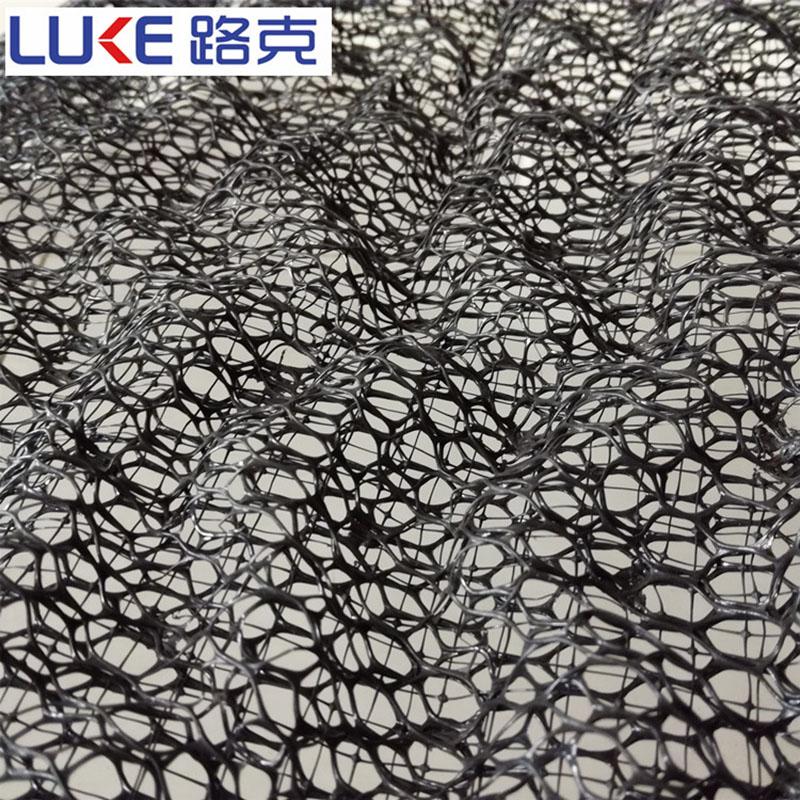

Product informationThe strengthened geomat is pp mesh mat composited with twine mesh, this is galvanized in case of abrasion manipulate.The form allows enough location for keeping the soil and grass growing.

Contacta ahora

The geocell is three dimensional, honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique. It is flexible to fold during the transport and installation on construction site.

Contacta ahora

Product informationThe strengthened geomat is pp mesh mat composited with cord mesh, that is galvanized in case of erosion manipulate.The shape allows enough area for maintaining the soil and grass growing.

Contacta ahora

Product DetailsDrainage sheet mat is made of plastic core and filtering cloth.In the state of hot melting,it is formed into three-D network structure.It has two shapes:rectangle and round.This kind of pipe has some advantages:good drainage,high pressure resistance,light weight,so it is very popular in some projects.ParameterPropertiesCDK-05CDK-06CDK-08CDK-10CDK-15CDK-20Thickness568101520Pressure Resistance250Kpa280KpaStretch Rate≥6.0Kn/mElongation Percentage≥40%Porosity 80-90%Horizontal Hydraulic Conductivity200Kpa,≥5.0x10-3 M²/sFeature* Flexible and durable* High Tensile Strength and Low Elon

Contacta ahora

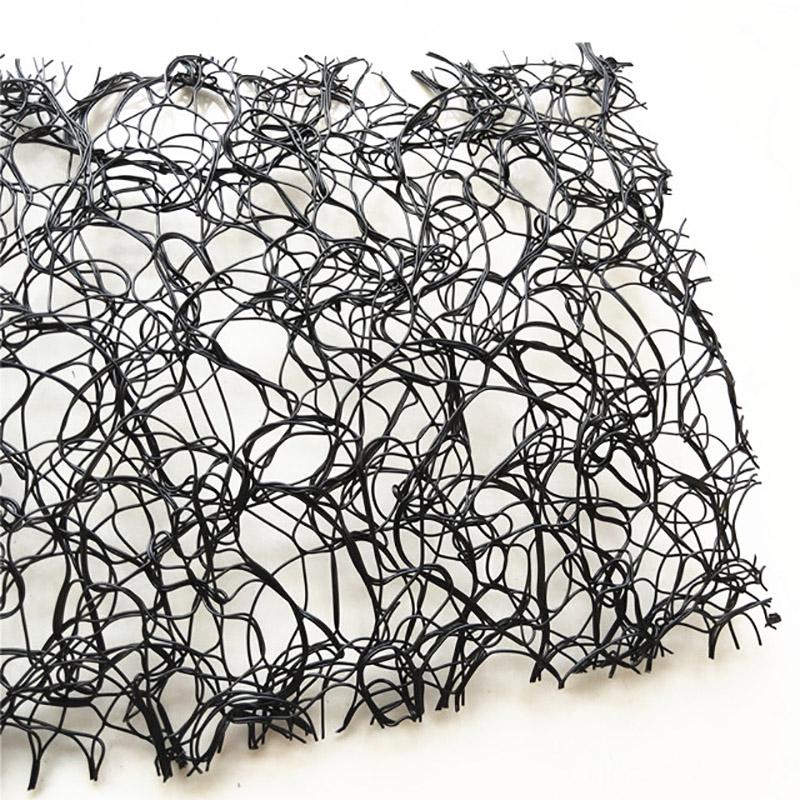

Product Details3D Geomat is like a gourd network three-dimensional structure for the planting soil, loose and flexible, with a 90% space filling soil, gravel and fine stone, plant roots can intervene, comfortable, orderly and balanced growth after growing grass mat, turf, soil.

Contacta ahora

Product DetailsReinforced 3D Geomat Erosion Control Mat for Soil Stabilization Slope Protection Geomat3D geomat is sort of a gourd community three-dimensional shape for the planting soil, unfastened and bendy, with a 90% space filling soil,gravel and excellent stone, plant roots can interfere, at ease, orderly and balanced increase after growing grass mat, turf, soil.The surface tightly collectively, because the plant roots deep below the floor of 30 - 40 cm, forming a defensive layer of inexperienced composite strong.Before the turf grows, it protects the surface of the soil fr

Contacta ahora

Product Details3-D geomat is like a gourd community three-dimensional shape for the planting soil, loose and flexible, with a ninety% space filling soil, gravel and excellent stone, plant roots can interfere, relaxed, orderly and balanced growth after developing grass mat, turf, soil.The surface tightly collectively, due to the fact the plant roots deep beneath the floor of 30 - 40 cm, forming a defensive layer of inexperienced composite stable.Earlier than the turf grows, it protects the floor of the soil from rain and wind.It could firmly keep the seeds lightly dispensed at the slope, from t

Contacta ahora

Product Details3-D geomat is like a gourd community three-dimensional shape for the planting soil, loose and flexible, with a ninety% space filling soil, gravel and excellent stone, plant roots can interfere, relaxed, orderly and balanced growth after developing grass mat, turf, soil.The surface tightly collectively, due to the fact the plant roots deep beneath the floor of 30 - 40 cm, forming a defensive layer of inexperienced composite stable.Earlier than the turf grows, it protects the floor of the soil from rain and wind.It could firmly keep the seeds lightly dispensed at the slope, from t

Contacta ahora