Product Details The filament Non-woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure. It is a kind of new material in geotechnical and engineering project. Except for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkali resistance and anti-aging. The wider opening size allows it has good permeability and filtration.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21

Contacta ahora

Product Details The filament non-woven geotextile is made from polyester lengthy fiber forming into net and consolidation with three size shape. It is a type of new fabric in geotechnical and engineering task.Except for its precise mechanical residences of tensile energy and puncture resistance,it additionally had excellent drainage capability,acid and alkali resistance and anti-getting older.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21.61.92.22.52.83.13.44.25.5Width Variation%-0.5Break StrengthKN/m4.57.510.512.515

Contacta ahora

Product Details The filament Non-woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure.It is a kind of new material in geotechnical and engineering project. Except for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkali resistance and anti-aging.The wider opening size allows it has good permeability and filtration.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21.61.92.22.52.83.13.44.2

Contacta ahora

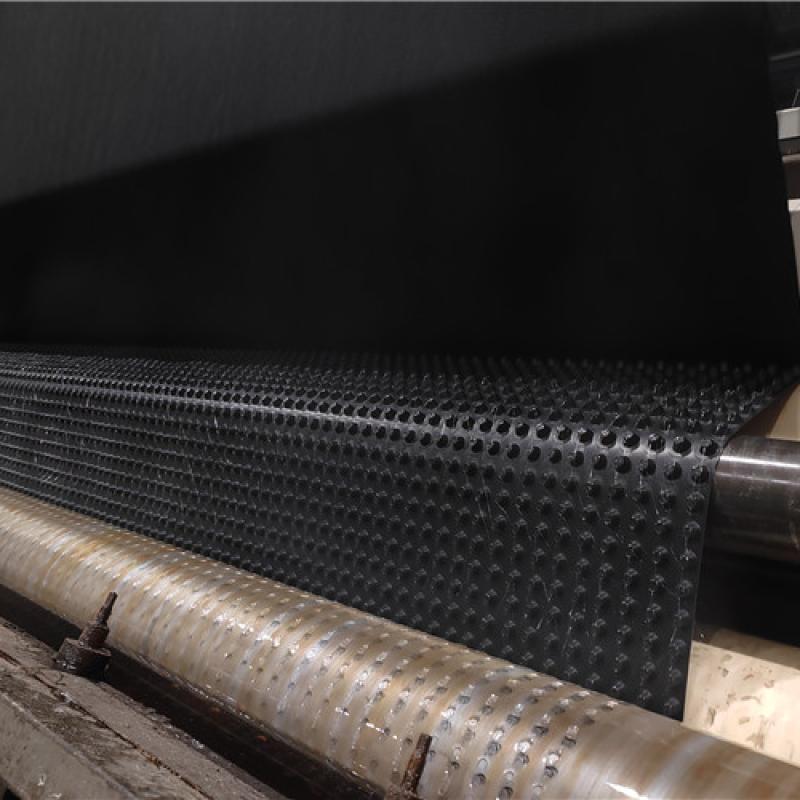

Product Details The Woven geotextile is produced by virgin polypropylene fiber ,is made of at least two rows of parallel yarns(or tape yarn),using different weaving machines and technologies to weave the warps and wefts into textile shape with various thickness and compactness according to usage ranges. In general,woven geotextile is with relatively light in weight,strong tensile strength,smaller elongation as well as brilliant stability. Our Polypropylene woven geotextile is relatively light in weight, strong tensile strength, smaller elongation as well as brilliant stability.

Contacta ahora

Product Details The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness. Geotextiles play an important and crucial role in the civil engineering works. The wide spectrum of geotextiles and related products that are available to civil engineers to solve a wide range of problems along with their functions and possible applications. Geotextiles are permeable textile structures made of polymeric materials and are used mainly in civil engineering applications in conjuncti

Contacta ahora

Product Details The needle-punched non woven geotextile is comprised of polyester or polypropylene fiber with the aid of unique system and era to get special thickness. Geotextiles play an critical and crucial role within the civil engineering works. The huge spectrum of geotextiles and associated products which might be to be had to civil engineers to remedy a huge variety of troubles along with their capabilities and feasible applications. Geotextiles are permeable fabric systems product of polymeric materials and are used specifically in civil engineering applications to

Contacta ahora

Product Details The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness. Geotextiles play an important and crucial role in the civil engineering works. The wide spectrum of geotextiles and related products that are available to civil engineers to solve a wide range of problems along with their functions and possible applications. Geotextiles are permeable textile structures made of polymeric materials and are used mainly in civil engineering applications in conju

Contacta ahora

Product Details The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by way of special equipment and era to get specific thickness. Geotextiles play an crucial and critical position within the civil engineering works. The huge spectrum of geotextiles and related merchandise which are available to civil engineers to clear up a huge range of problems along with their functions and viable packages. Geotextiles are permeable fabric structures made from polymeric materials and are used specially in civil engineering packages i

Contacta ahora

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contacta ahora

Product Details The filament Non-woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure.It is a kind of new material in geotechnical and engineering project. Except for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkali resistance and anti-aging.The wider opening size allows it has good permeability and filtration.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21.61.92.22.52.83.13.44.2

Contacta ahora