Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contacta ahora

Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Contacta ahora

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contacta ahora

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contacta ahora

Product Details Twisted package pp fiber is developed for replacement of metallic fiber. With polypropylene as its raw material,it's far produced by way of special drawing twisting and surface remedy. Compared with metallic fiber, it has benefits of acid, alkali resistant, first rate tensile, clean dispersing, comfort for creation and no harm to the combination system. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwi

Contacta ahora

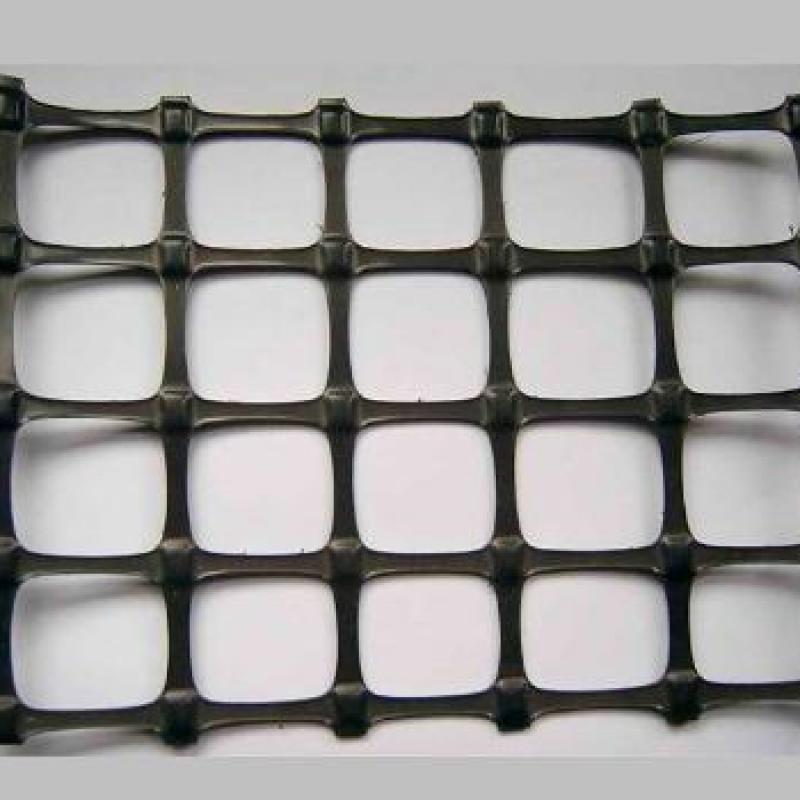

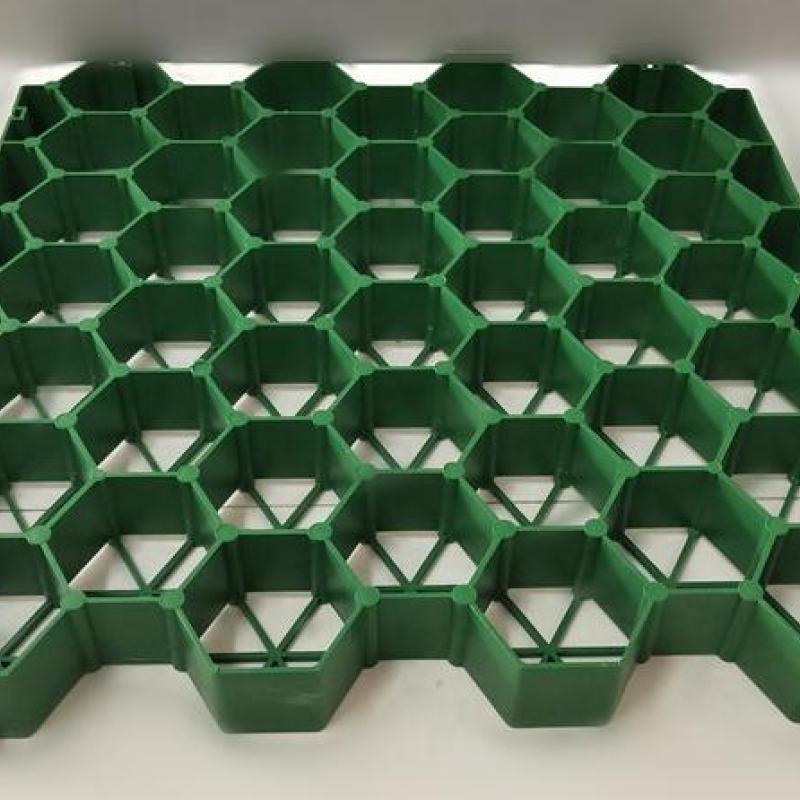

The geocell is three dimensional, honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique. It is flexible to fold during the transport and installation on construction site.

Contacta ahora

Geocell Ground Grid HDPE GeocellsWhat is Geocell Ground Grid HDPE Geocell?Geocell is a new type of geosynthetic material, also known as geocell grid network. It is a high-strength HDPE or PP sheet that is welded or braided by ultrasonic waves to form a honeycomb-like three-dimensional structure. When the geocell is developed, it can become a three-dimensional structure that can withstand great pressure and strain.

Contacta ahora

Concrete Fiber Polypropylene PP Fiber MeshPolypropylene mesh fiber is a kind of polypropylene particles as raw material, which is specially processed and treated. Add to the concrete base material. After stirring, the monofilament fiber or mesh structure fiber is fully opened, forming a chaotic support system inside the concrete. Polypropylene pp fiber mesh can effectively control the early plastic shrinkage and settlement cracks of concrete and cement mortar.

Contacta ahora

1.0mm 1.5mm 2.0mm HDPE Geomembrane For LandfillThe thickness of the anti-seepage film for landfill is usully between 1.0~2.0mm.The anti-seepage film used in landfills,also known as HDPE geomembrane(HDPE geotechnical film),is a waterproof barrier material with polyethylene primary resin as the basic raw material.This geomembrane is mainly used to prevent garbage leachate from penetrating into the ground and avoid polluting groundwater.According to different stages of use and requirements,the thickness of HDPE geomembrane varies.Technical parameters of 1.0mm 1.5mm 2.0mm HDPE Geomembrane For

Contacta ahora

Product DetailsGarage and drainage board is product of pp material,an new geotechnical fabric which garage a set of water drainage,water garage characteristic,and also have the water drainage,water storage,breathable,moisture,thermal insulation,save you multiple features inclusive of plant roots destruction for concrete systems.Used combination with geotextile can avoid the first-rate particle plugging water storage tank and drainage channel,hold clear of drainage and air circulation,that's extensively utilized in garden greening initiatives.ParameterModel MaterialDrain height(mm)Compressi

Contacta ahora