Anti Crack Concrete Fibers for Sale

Polyolefin Polypropylene Macro Structural Synthetic Fibers For Sprayed concrete

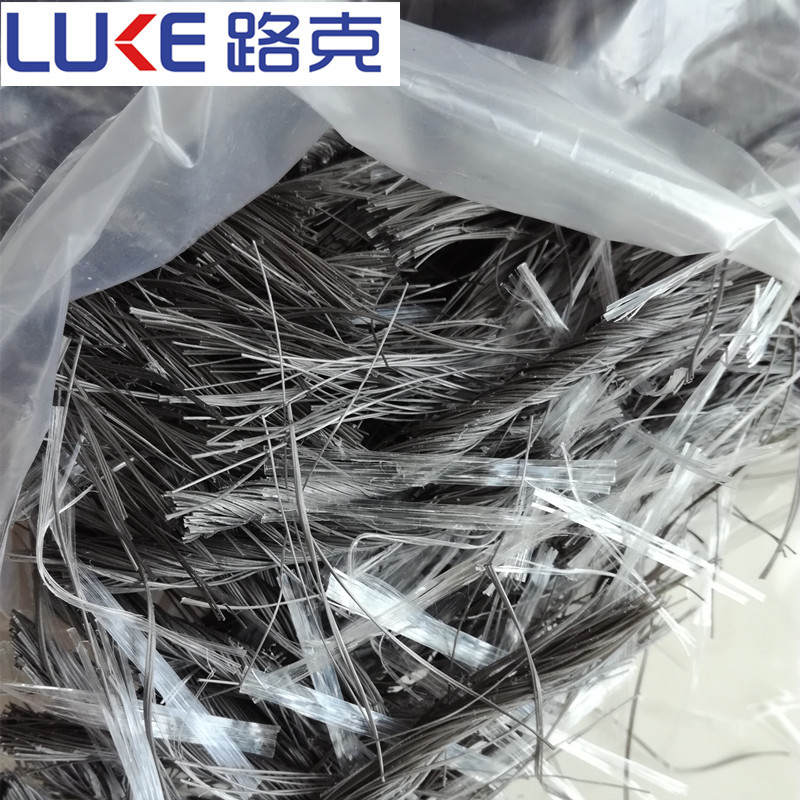

Macro Synthetic Fiber Concrete, Anti Crack Concrete Fibers

Anti Crack Concrete Fibers - Polypropylene Twisted Fibers

Twisted bundles PP fiber is developed for replacement of steel fiber, with polypropylene as its raw material;it is produced by special drawing twisting and surface treatment. Compared with steel fiber, it has advantages of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to the mixing equipment.

( Mix with Fibrilled Mesh Fiber)

Technical Parameter

(g/cm3)Density | 0.91 |

(mm)Length | 38mm, 54mm or as your request |

Shape | Twisted bundle |

(MPa)Tensile Strength | >400 |

Elastic Modulus(MPa) | >4000 |

(mm)Diameter | 0.3±0.05 |

(%)Crack Elongation | 20±5 |

Melting Point | >160℃ |

Functions:

1. Can reduce damage when happened earthquakes and other natural disasters.

2. To reduce fatal flaws in concrete

3. To reduce the leakage of concrete

4. To protect steel from corrosion

5. To improve the durability of concrete structures

6. Increase the wear resistance of concrete

7. Increasing the concrete crack resistance, flexural strength, increased toughness of concrete, to extend the life of concrete binder

8. no agglomeration and easily spreads around in mortar or concrete,

9. Guaranteeing the property of crack resistance effectively

10. convenient applying: No need to change the proportion of mortar, andjust put the fibers into the mortar mixture and stir for a moment afteradding water.

11. fine economic property.

12. the fiber has stable chemical property, strong acid and alkali resistance, and can be used in any engineering projects.

Productos relacionados

Noticias relacionadas

Presentado con éxito

Nos pondremos en contacto con usted lo antes posible